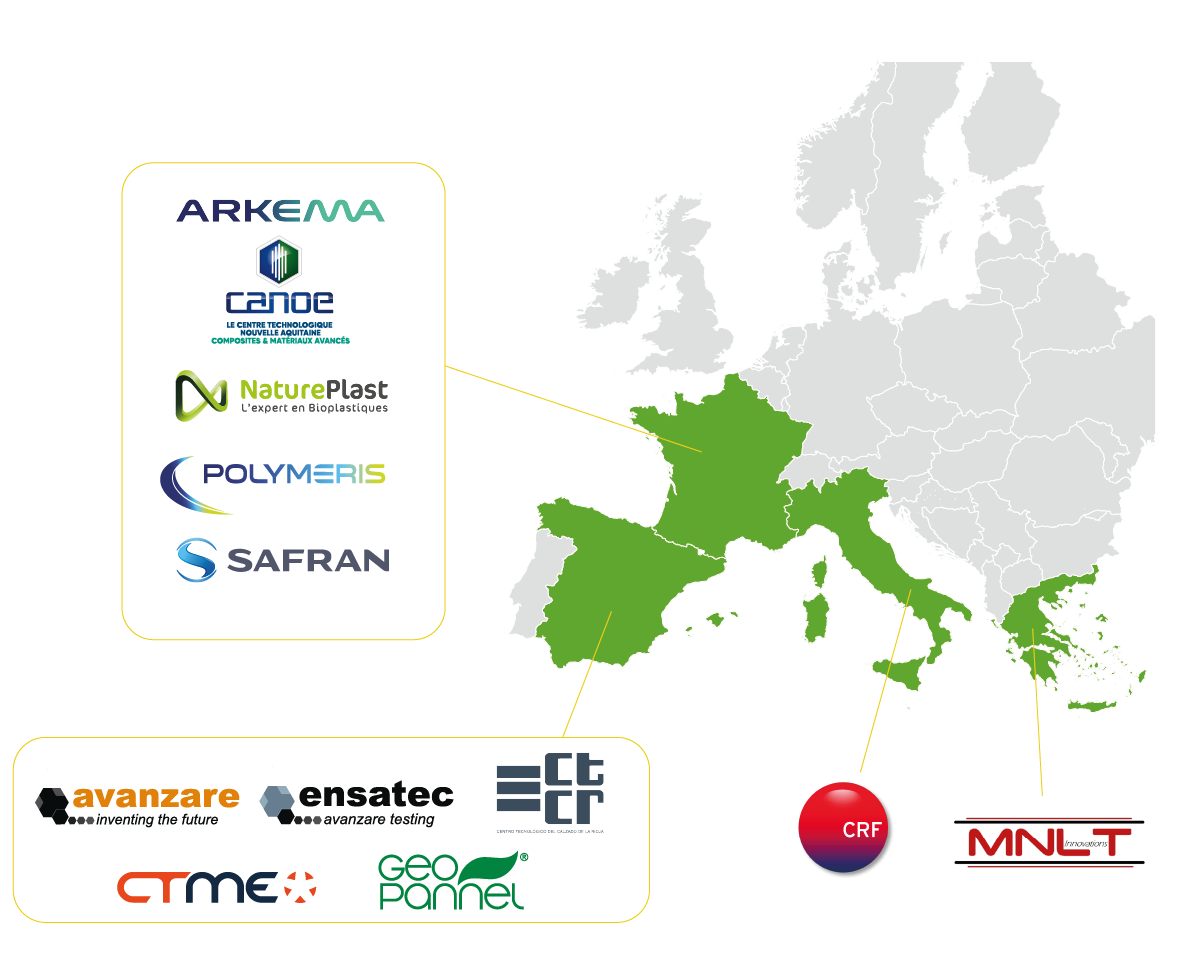

The project partners

AVANZARE is the coordinator of THERMOFIRE project and WP7 leader.

AVANZARE is a Spanish Company, for near two decades building capacity, upscaling over and been the leader in the production of emerging and advanced material, chemical high value solutions and specialized in the production of 2D materials (Graphene, GO, rGO, h-NB, Mo2S, and other inorganic 2D, and complex heterostructures by layer self-assembly of 2D materials and layer by layer deposition).

AVANZARE was the pioneer in the industrial manufacturing of GRMs. And the 1st company showing graphene and graphene based product in an exhibition fair: NANOTECH JAPAN 2009. We are present in numerous industries, among others: automotive (>50%), plastic, rubber, energy production, energy storage, painting, building industries, packaging and paper, electronics, wire and cable sector. Avanzare provides customers with high-performance nanomaterials and nanotechnology-based solutions. We are specialized in the development, production and commercialization of specialty additives for materials like plastic and rubber. We are now internationally present across numerous industries: automotive, aeronautics, safety equipment, footwear, painting, building wire and cable sector, fabrics, packaging and paper etc.

ENSATEC – Technological accredited entity. Will perform in close collaboration with AVANZARE characterization tests during the project mainly, flammability tests (WP2-4). ENSATEC has equipment relevant to the project such as burning chambers according to several standards.

We offer Testing, Calibration, Inspection and Product Certification services. We are an ENAC accredited center and Notified Body NB Nº1668 for the Construction Products Regulation.

We develop our activity through several laboratories and departments: Fire, Acoustics, Enclosures, Thermal testing, Mechanical testing, Climatic/aging tests, Biotechnology, New Materials, Product Certification, R+D+i Services

We offer a comprehensive service, from design assistance to complete product characterization, in a single specialized center.

MNLT Innovations P.C. was established in 2018 in Athens, Greece, as a spin-off of Monolithos Catalysts and Recycling Ltd. and constitutes an independent business development/engineering consultancy SME, operating according to EU standards. MNLT brings multi-year knowledge and expertise in the field of industrial minerals and metals, catalytic and construction materials, energy and recycling, and is offering quality services that cover the whole process towards the full development of a business, from the ideation stage to the successful entry in the market. The service portfolio includes: business development and outreach activities, continuous monitoring and support, market analysis and competitive positioning determination, and life cycle assessment (LCA-LCCA-SLCA). MNLT participates in more than 10 EU cross collaborative projects developing go-to-market strategies, outreach and marketing plans for the innovative outputs towards a successful market uptake

CTME was founded in 1992 as Non-profit Research Association, becoming Research Foundation in July 2007. Partnership comprises the most relevant private companies in the industrial area of Miranda de Ebro, ranging a large variety of industrial sectors: energy, construction, machine-tool, aeronautics and automotive.

Today CTME has two distinct areas of business:

1) RTD, in which CTME wants to be a European benchmark in environmental sustainability through its different lines of research,

2) Laboratory services, with four specialized and accredited laboratories to provide services to the aeronautical sector.

The RTD team is involved in a continuous “open-innovation” line-management process in order to accrue enough knowledge and capacities to face any challenging research project for industry.

CTME offers 4 high-tech and excellent research areas:

1. Sustainable management: Life Cycle Assessment (LCA) and Life Cycle Costing (LCC), Environmental Product Declaration (EPD), Product Categories Rules (PCR), eco-design.

2. Software engineering: FIWARE applications, Internet of Things, Industry 4.0, Blockchain...

3. Polymers, biopolymers and composites: formulation and transformation of plastics from renewable sources.

4. Thermal sprayed coatings.

Over the last 19 years, CTME’s intensive work in LCA, LCC, eco-design and environmental communication has contributed to reaching an avant-garde position and leadership in Sustainable Management, being involved in a number of Innovation Projects for different sectors: automotive industry, aeronautic, machine-tools, alimentary, etc., as example CTME´s Environmental Sustainability Department has participated performing LCA studies in H2020 Projects like FTI NATUREFREHS, EUROSTART FUNPLASTIC, EUROSTART ECOPROTEC, CS2 NEMARCO, CS2 AMANECO, CS2SEALANT and CS2 ECOLAND

CANOE is an R&T center based in the Nouvelle-Aquitaine region, specializing in the formulation and manufacturing processes of polymer materials for the development of composites and advanced materials.

CANOE's main objective is to support small- and middle-sized enterprises (SME) as well as large industrial groups, in the development of new products and processes through pilot line capabilities (from TRL3 to TRL6): R&D services (feasibility study, prototyping, scale-up demonstration, materials testing….), R&D cooperative projects (national and European) and training courses. CANOE mainly addresses the following application sectors: transport (automotive, aerospace, railway, marine industry…), defense, renewable energy (electrode and pack for battery, H2 pressure composite storage vessel, wind energy composite blade, photovoltaic panel), sustainable building, sport and leisure.

Role within THERMOFIRE:

CANOE will be involved in the following tasks: (1)Development of the flame-retardant polymer formulation, (2)Development and production of the cellulose fibre, (3)Manufacture of the aeronautical demonstrator (in collaboration with SAFRAN), (4)Study of mechanical recycling methods, WP(2) Manufacture tape made of naturel fibers : flax and cellulose.

CTCR – The Footwear Technology Centre of La Rioja (CTCR), located in the North of Spain serves as the hub of the footwear sector in the area, providing innovative research and development solutions to its companies. The CTCR was constituted as a private non-profit association with the aim of increasing the competitiveness of businesses, creating added value in products and production processes.

The CTCR has more than 120 partners, and the 80% of these partners were manufacturers or distributors of footwear. Our staff is about 35 people and we carried out around 30 projects yearly. We have our own laboratory in our headquarter, that allow us to validate the results of R&D projects.

The CTCR has the knowledge and the human and material resources for the development of RDI projects in the following three big areas of business:

- Sustainability and Advanced Materials, thanks to our knowledge in Nanotechnology. Sustainability, that includes projects about Biotechnology and Ecofriendly manufacturing processes.

- Digital Transformation, thanks to ICTs. The projects of this department range from RFID solutions, Business Intelligence, Machine Vision applications, augmented reality applications, Big Data and Blockchain.

- Smart Manufacturing that includes Technology such as: Electronic and Automation and Mechanics and Prototyping

GEOPANNEL (ANGEL RUIZ IBAÑEZ, S.A.) is a 75-year-old family-owned company dedicated to manufacture nonwoven products of all kind, and specialized in acoustic, thermal and mechanic properties of felts and 3D molded parts using felts as a base.

In the consortium our tasks will be:

Investigating, developing and manufacture feasible prototypes coming from natural fibres and sustainable polymers. Working together with the different consortium partners Geopannel will develop new formulas with low carbon footprint materials and process orientated to architectural, aeronautics and automotive products, achieving the targets in terms of acoustics, fire behaviour, and mechanic and thermal properties needed for all the cases. During the project Geopannel will select materials, test them in process, define, improve and manufacture prototypes to a scale than can be tested and homologate in Stellantis (OEM consortium partner), and/or the different sectors such aeronautics/train manufacturers, architectural performances, etc.

New products will be developed for the automotive, aeronautics and construction sectors, which, having the same technical characteristics as the current ones, offer a development with natural fibres as opposed to the use of plastic materials.

GEOPANNEL will also use its internal lab facilities to investigate mechanical properties, automotive’s fire regulation, and thermal and acoustic properties of the materials developed.

Created in 2007, NaturePlast is dedicated to the development of biobased and/or biodegradable plastics. The company guides industries in customized projects in many sectors such as agriculture, packaging, luxury goods, cosmetics and many others. NaturePlast can supply most of the biopolymers produced worldwide at industrial scale, and develops customized compounds thanks to its R&D center BiopolyNov. The company is also working on the incorporation of by-products (seashells, short vegetal fibers, etc) into the polymer matrixes to bring new properties and create new design.

POLYMERIS Dissemination and valorization of the results will be performed by Polymeris (FR), a cluster with a large EU network in the field of polymers and composites for various industrial sectors.

ARKEMA – Arkema is a worldwide leader in specialty materials. Building on its unique set of expertise in materials science, Arkema designs materials to address the ever-growing demand for innovative and sustainable materials, driven by the challenges of new energies, new technologies, the depletion of resources, clean mobility and increasing urbanization. The Group is structured into three coherent and complementary segments dedicated to Specialty Materials (Adhesive Solutions, Advanced Materials, and Coating Solutions) accounting for 91% of its sales, and an Intermediates segment leveraging competitive and global product lines. Each of the business segments benefits from a global leadership positions for most of its business, a great capacity for innovation oriented towards sustainable development and environmental protection and a global geographical presence balanced between America, Europe and Asia.

Concerning innovation, Arkema cultivates interaction with its stakeholders and innovates around 5 solution-oriented research platforms (Lightening of materials, New energies, Natural resource management, Solutions for electronics, Home comfort and performance). These platforms articulate the Group's R&D with the major trends of today's and tomorrow's world.

Sustained by the collective energy of its 21,100 employees, Arkema operates in some 55 countries and reported sales of €11.5 billion in 2022.

Safran is an international high-technology group, operating in the aviation (propulsion, equipment and interiors), defense and space markets. Its core purpose is to contribute to a safer, more sustainable world, where air transport is more environmentally friendly, comfortable and accessible. Safran has a global presence, with 83 000 employees and sales of 19.0 billion euros in 2022, and holds, alone or in partnership, world or regional leadership positions in its core markets. Safran undertakes research and development programs to maintain the environmental priorities of its R&T and innovation roadmap.

Safran offers everything needed to outfit aircraft cabins: passenger seat, overhead bins, doors, lavatories, galleys, chariots and other food and beverage equipment, rest areas, containers, etc. To ensure top-flight quality, Safran provides support services for cabins on all types of aircraft: mainline, regional and business. We design aircraft cabins as an integrated whole to provide unrivaled space and operating efficiency, while also making things easier for our customers, airlines and other operators and of course the passengers.

CRF – the global automaker and mobility provider - is one of the end users of THERMOFIRE products. CRF will provide information about the material properties used in automotive for the production of the battery cover and the relative standards for the component validation (WP1 Leader). CRF also test and validate the housing made of the bio-based TP composites for electrical batteries. CRF has the capacity to conduct the automotive validation: aging reliability (UL94 flammability testing)